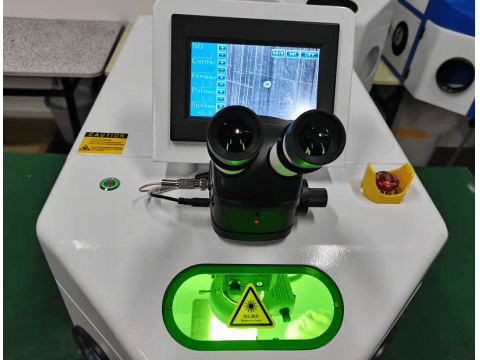

Jewelry Laser Welding Machine

Jewelry Laser Welding MachineJewelry Laser Welding Machine Spot Welder Gold Silver

The Jewelry Laser Welding Machine is a Spot Welder for Gold Silver Stainless steel, This welder offers precise and controlled spot welding, making it ideal for delicate jewelry pieces made of gold and silver. user can put workpiece under laser hea freely. whether you are repairing a broken piece or creating a new masterpiece, this jewelry laser welder is a valuable addition to any jeweler's toolkit.

Spot Laser Welders for Jewelers

Find the Perfect Jewelry Laser Welder

Key Highlights

Enhance Precision and Productivity: Experience a significant boost in the precision and speed of your jewelry-making processes.

Reduce Repair Times: Laser welders can cut down jewelry repair times by up to 50%

Expand Your Service Offerings: Offer a wider range of services, including eyeglass, watch, and even medical tool repair with the versatility of a laser welder.

Introduction

In the detailed field of making and fixing jewelry, being precise is very important. A laser welder and engraver is a key tool for jewelers who want to improve the quality of their work . Whether you are making custom items or fixing beloved pieces, laser welders give you great accuracy and control. This guide will help you choosing the right laser welder for your jewelry business.

Understanding Jewellery Laser Welding

Jewelry laser welding is a careful and effective method. It uses a focused laser beam to make heat and join metal pieces together. Unlike traditional soldering, which uses a torch and filler metal, laser welding bonds without extra materials. This makes the finish cleaner and better looking, which is very important for delicate and detailed designs.

In the process, a laser beam is aimed at a tiny spot on the jewelry piece. The strong energy melts the metal and forms a weld pool. This way allows for great control of the heat area, which lowers the chance of harming nearby stones or fragile parts.

The Basics of Laser Welding in Jewelry Making

The idea behind laser welding is simple. It uses a strong beam of light to create very high heat at one spot on the work piece. This heat melts the metal and joins it together. This creates strong and precise welds.

Laser welding can reach very high temperatures in small areas. This makes it good for many metals used in jewellery such as gold, silver, platinum, and titanium.

Benefits of Using Laser Welders for Jewelry

Jewelry Laser welders have changed the jewellery industry in many ways. One key benefit of laser welding is that it creates strong and nice-looking welds without using solder or filler materials. This makes a clean and polished finish, which is great for complicated designs.

Key Features to Look for in a Jewelry Laser Welder

Choosing the right laser welder is important for your jewelry business. You need to think about the types of metals you use the most, how complex your designs are, and your budget. All these factors will help you find the best machine for your workshop.

Power and Precision: Matching Your Needs

When picking a laser welder for jewelry, power and precision are very important. The power of a laser welder is measured in joules. It shows how well it can generate heat and join metals. Higher wattage means faster welding and the ability to work with thicker metals, there have 60w 100w 200w 300w in market. 200W is the most popular type in last several years.

Ease of Use and Maintenance

When choosing a laser welder with a touchscreen, think about how easy it is to use and care for. A simple interface with clear controls will help you learn quickly and let you focus on your work. Look for welders that have helpful features like preset modes for common jewelry metals, adjustable power settings, and displays that are easy to read.

Taking care of your laser welder is just as important. A machine that is properly maintained will work better and last longer, giving you good value for your money. Pick a model that has easy maintenance steps, available replacement parts, and clear cleaning instructions.

If you have a small workshop, choose a compact and lightweight laser welder. This way, it won't take up too much space, mini type is suggested in shop.

Conclusion

To create beautiful and detailed jewelry, picking the right laser welder is very important. It’s good to know the benefits of laser welding in jewelry making. This includes its precision and ease of use. When you choose a jewelry laser welder, think about power, precision, and how easy it is to maintain. A laser welder can work with delicate gold pieces or stronger metals. Also, remember to focus on safety and choose a model that fits your budget and business needs. Make a smart choice to improve your jewelry crafting with the right laser welder.

Factors to Consider When Choosing a Jewelry Laser Welder

Before you choose a laser welder, think about a few important things that match your business needs:

Budget: High-end laser welders can be expensive. There are also many affordable options that suit different budgets, especially for small businesses and new companies. Check your finances carefully and look into financing or leasing options.

Workspace: Look at the size of your workspace. Pick a machine that fits well while keeping ergonomics and safety in mind.

Metals Used: Laser welders work better with specific metals. Make sure the welder you pick can handle the metals you use most. If you handle many types of metals, a more flexible model might be best.

Frequently Asked Questions

What types of jewelry can be laser welded?

Laser welders work well with many types of