Easy to transport Portable 20w 30w 50w raycus fiber laser marking engraving machine pric

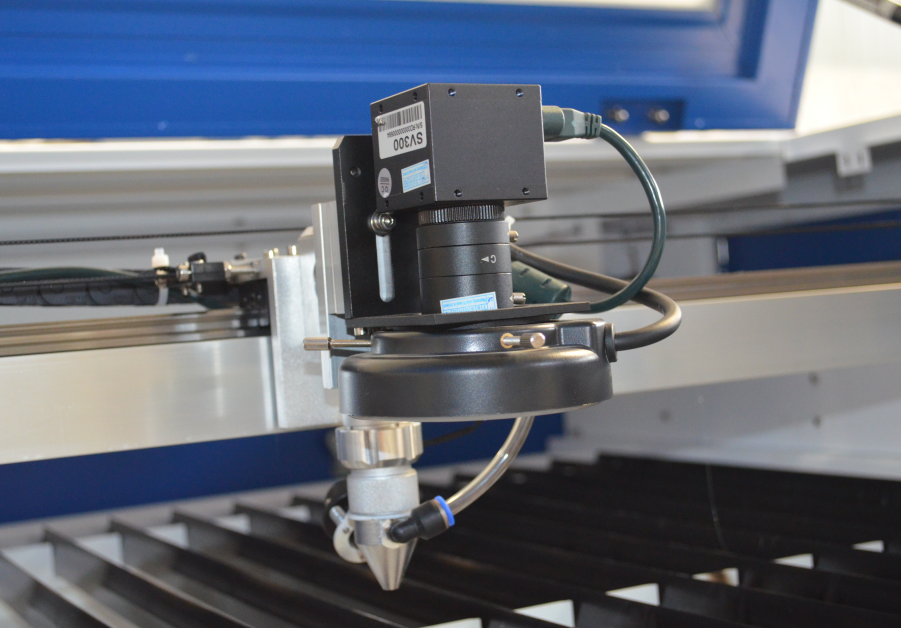

This fiber marking machine we called ALL-IN-ONE model. This model is mainly composed of these Machine Prats Laser source Laser Galvo head,F-theta lens and Ezcad control board and so on. There have Laser Power Supply and Galvameter Power Supply Button on front of laser marking machine, all our machine have CE AND FDA Certificate.